At Reliance Industrial Services Ltd, we provide a comprehensive range of Non-Destructive Testing (NDT) and inspection solutions designed to ensure safety, reliability and compliance across industries. Using both conventional and advanced techniques, our expert team deliver accurate results that help clients maintain asset integrity, reduce downtime and optimize performance.

Conventional NDT Methods

Radiography Testing (RT)

X-ray and gamma-ray imaging to reveal hidden internal defects in welds and materials using Conventional, CR and DR technology.

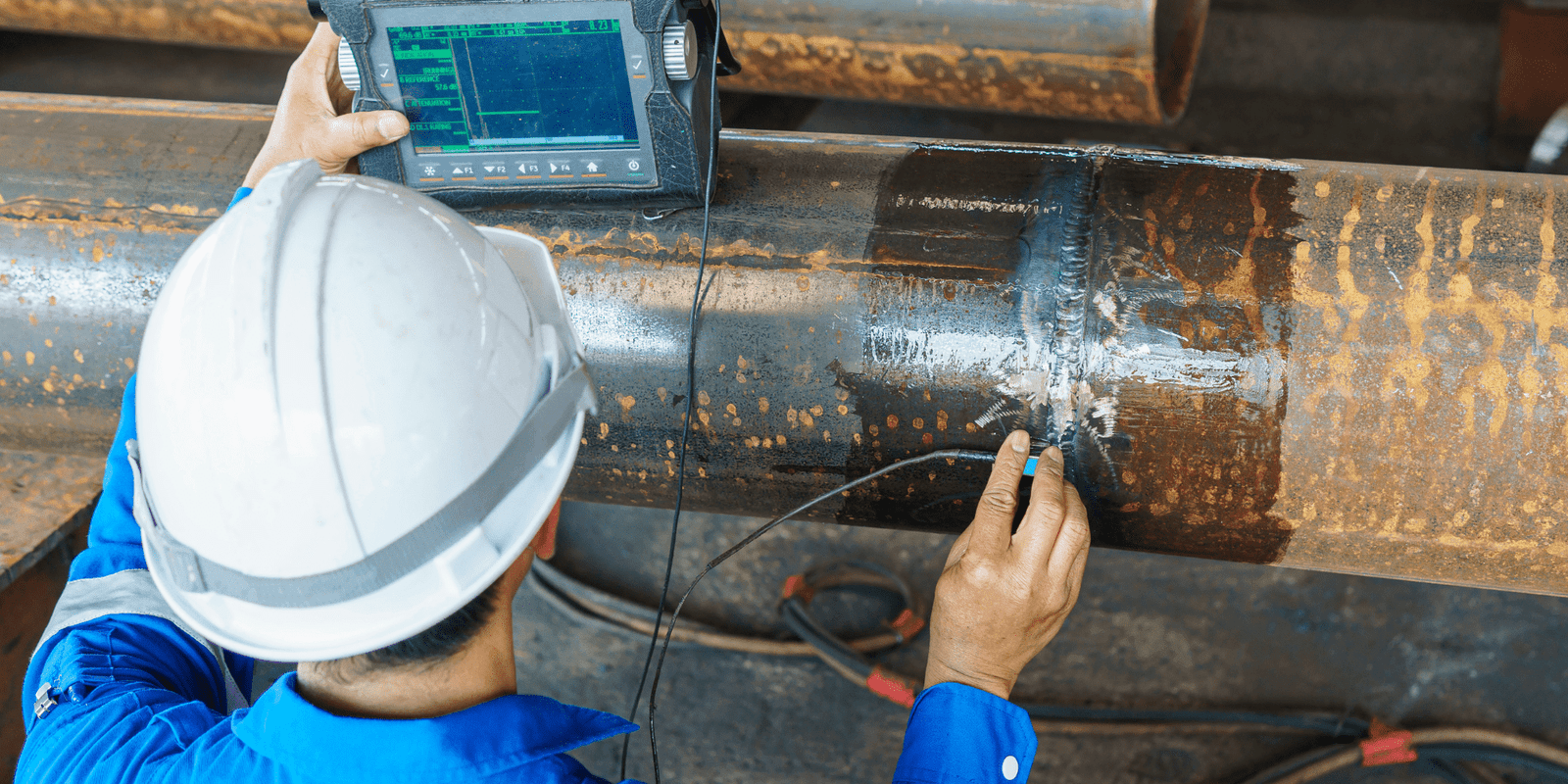

Ultrasonic Testing (UT)

Identify internal flaws and check material thickness with high and low-frequency sound waves.

Magnetic Particle Testing (MT)

Using current flow magnetic flux induction and permanent magnetic techniques, with fluorescent and daylight viewing inks to find surface and near-surface defects in ferromagnetic materials.

Liquid Penetrant Testing (PT)

Apply fluorescent or visible dyes to detect surface cracks and leaks.

Vacuum Leak Testing

To detect leaks in condenser, boilers, and heat exchangers tubes as well as tank floor, roof and shell.

Advanced NDT Methods

PAUT (Phased Array UT)

Advanced ultrasonic imaging that delivers precise weld and material inspections.

MFL (Magnetic Flux Leakage)

Rapid detection of corrosion and defects in pipelines and tank floors using magnetic fields.

TOFD (Time of Flight Diffraction)

High accuracy crack detection and sizing for reliable weld assessment.

Thermography

Infrared scanning to spot hidden faults through temperature variation, fast and non-contact.

Tube Inspection

Specialized testing to detect corrosion, pitting and wear in heat exchanger and boiler tubes. ECT, IRIS, RFT & MFL.

Material Identification & Verification

PMI (XRF and OES) - Positive Material Identification

On-site alloy verification to confirm correct material grade and chemical composition.

Ferrite Content Inspection

Ensures proper ferrite levels in stainless steels for durability and resistance to cracking.

Portable Hardness Testing

Applying a constant load under controlled conditions to create an indentation in a metal surface then measured to determine the hardness of the material.

Visual & Remote Inspection

Borescope Inspection

Visual inspection of hard-to-reach areas using high-resolution camera technology.

Visual Testing (VT)

Direct and remote visual inspections to identify general deterioration on material.

Why Choose Us?

With a blend of cutting-edge technology and industry expertise, we deliver fast, reliable, and cost-effective inspection services tailored to client needs. Our commitment is to help industries achieve the highest levels of quality, safety and operational excellence.